Wasp Barcode Technologies: The Barcode Solution People

GHS, HCS Standards Changing Chemical Drum Labels

Ensuring the safety and health of American workers is the primary goal of the Occupational Safety & Health Administration (OSHA). Other countries share this objective, which is why world leaders are tackling the challenges and risks of transporting chemicals and other hazardous products across domestic and international borders.

Through the United Nations, they’ve created the GHS (Globally Harmonized System), which standardizes the classification and labeling of chemicals. This system specifically addresses the requirements for drum labels due to growth projections of this market, which this year are estimated to top $50 million in North America alone.

Drum label market is rapidly growing

[caption id="attachment_5789" align="alignright" width="300"]

The GHS standardizes chemical classifications and labels across the globe. OSHA defines requirements for North America through its HCS regulation.[/caption]

According to government reports, U.S. steel drum manufacturers produce approximately 27 million 55-gallon steel drums and recondition another 35 million each year. In addition, they produce 15 million plastic drums and recondition 5 million every 12 months.

The majority of these steel and plastic drums contain liquid and powder chemicals, petroleum, paints and coatings, food products, and additives. As such, their labels must meet certain requirements set forth by OSHA and DOT (the Department of Transportation). They must also adhere to the ANSI 129.1 guidelines for labeling hazardous industrial chemicals.

New regulations protect against hazards

In its newly revised Hazard Communication Standard (HCS), OSHA outlines safety and health protections for American workers. Regulation 29 CFR 1910.1200 defines environmental, physical, and health hazards from chemicals and outlines requirements for communicating these hazards and protective measures to employees and customers.

This includes labeling requirements for identifying, warning, and informing workers, along with durability specifications for resisting weather, scratches and tears, and chemicals/solvents. The regulation also defines mandates for safety data sheets and employee training.

What does this mean to you?

Chemical manufacturers, distributors, and importers are required to:

- Evaluate the hazards of the chemicals they produce or import.

- Prepare labels and safety data sheets that convey this information to their downstream customers.

- Supply their exposed workers with safety sheets and train them on processes for appropriately handling the chemicals.

Labels

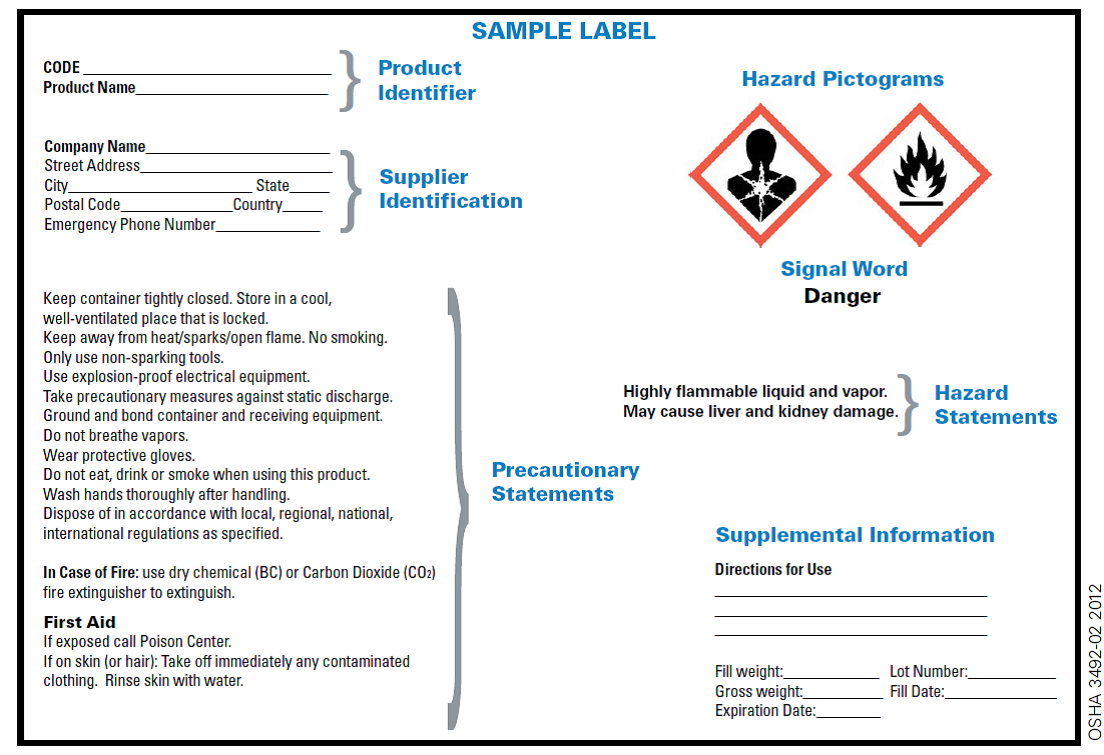

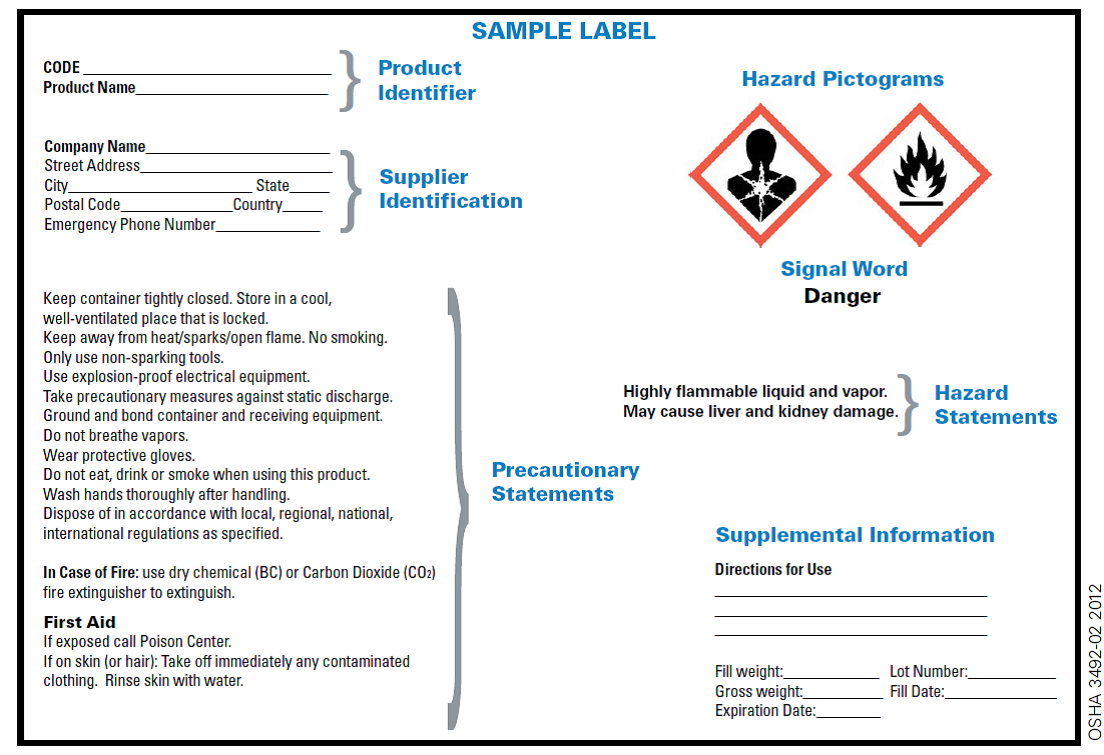

Starting in 2015,*each chemical drum label must include a product identifier, signal word, hazard statement, precautionary statement, supplier information, pictograms, and supplemental information (optional). This image from OSHA shows a sample layout using the required information, which is explained in more detail below.

[caption id="attachment_5792" align="aligncenter" width="1104"]

This illustration shows a sample layout for chemical drum labels. Source: Occupational Safety & Health Administration (OSHA).[/caption]

- A product identifier identifies the product ingredients and includes the chemical name, product name, and other any other unique identifiers. For mixtures, the label must include the chemical identities of all ingredients that contribute to the product’s toxicity.

- A signal word alerts handlers to the severity of the chemical hazard. Examples include the words “Danger” for more severe hazards and “Warning” for those that are less severe.

- A hazard statement describes the nature and degree of the hazard using standard, assigned phrases to hazard classes and categories.

- A precautionary statement describes recommended actions for minimizing and/or preventing adverse effects that result from exposure to the chemical or from improper handling or storage.

- Supplier information includes the manufacturer, importer, or other responsible party’s name, address, and phone number.

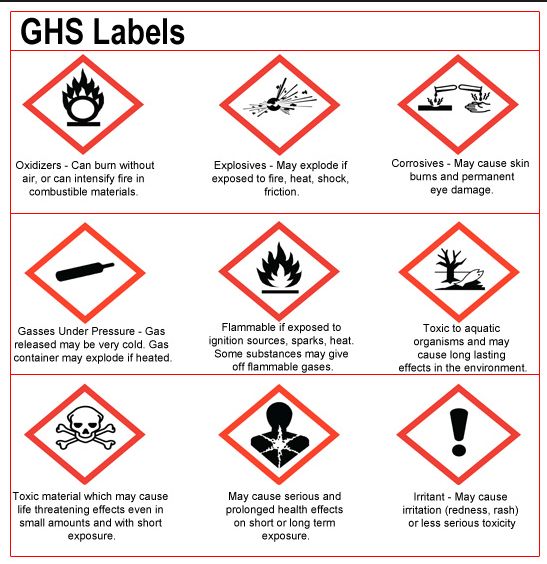

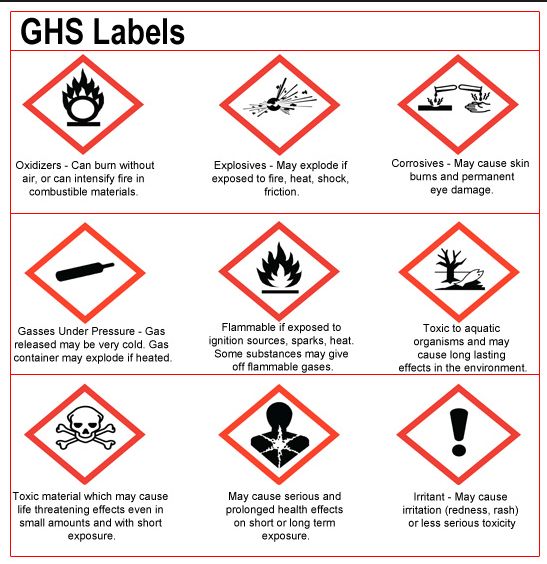

- Pictograms are visual indicators that include standardized graphics and symbols to alert workers and customers to a specific hazard. All pictograms contain consistent style elements, which include a black symbol on a white background framed by a red, diamond-shaped border.

- Supplemental information (optional) provides more details about the product, such as directions for use, weight, lot number, fill date, and expiration date.

[caption id="attachment_5794" align="aligncenter" width="547"]

This graphic displays the pictograms identified by the United Nations to visually alert workers to a specific hazard. Source: Repacorp, Inc.[/caption]

To comply with the requirement to include variable data on every chemical drum label, companies are opting for

labels that may be completely blank or preprinted with static information that doesn’t change, such as a company name or logo. Organizations can then add variable information to preprinted labels in-house using a high-performance

barcode printer.

These label printers enable on-demand printing so it’s easy to add information to either label type, both of which must meet HCS specifications for warnings, product information, durability, and pressure sensitivity.

Safety data sheets

To ensure uniformity and compliance with GHS regulations, OSHA requires companies to include 16 sections of information on their safety data sheets. Organizations must include the exact section numbers, headings, and associated information as outlined by the HCS.

- Section 1, Identification includes the product identifier; manufacturer or distributor name, address, and phone number, along with an emergency phone number; recommended use; and restrictions on use.

- Section 2, Hazard(s) identification includes all hazards regarding the chemical and required label elements.

- Section 3, Composition/information on ingredients includes information on chemical ingredients, along with trade secret claims.

- Section 4, First-aid measures includes important symptoms—including effects, acute, and delayed—and required treatments.

- Section 5, Fire-fighting measures lists suitable extinguishing techniques and equipment; it includes chemical hazards from fire.

- Section 6, Accidental release measures lists emergency procedures; protective equipment; and proper methods of containment and cleanup.

- Section 7, Handling and storage lists precautions for safe handling and storage, including incompatibilities.

- Section 8, Exposure controls/personal protection lists OSHA’s Permissible Exposure Limits (PELs); Threshold Limit Values (TLVs); appropriate engineering controls; and personal protective equipment (PPE).

- Section 9, Physical and chemical properties lists the chemical’s characteristics.

- Section 10, Stability and reactivity lists chemical stability and possibility of hazardous reactions.

- Section 11, Toxicological information includes routes of exposure; related symptoms, acute and chronic effects; and numerical measures of toxicity.

- Section 12, Ecological information*

- Section 13, Disposal considerations*

- Section 14, Transport information*

- Section 15, Regulatory information*

- Section 16, Other information includes the date of preparation or last revision.

*Note: Since other agencies regulate this information, OSHA will not be enforcing Sections 12 through 15.

For additional information, refer to OSHA’s

Small Entity Compliance Guide for Employers That Use Hazardous Chemicals.

Don’t miss these critical dates*

Employee training on label requirements and safety data sheet formats began in December 2013 and continues through 2014. That said, manufacturers, importers, distributors, and employers have until 2016 to fully comply with OSHA’s regulations.

In 2015, the HCS mandate starts rolling out a phased approach for compliance with global GHS standards. Critical deadlines include:

- June 1, 2015 – Chemical manufacturers must comply with all final rule provisions.

- December 1, 2015 – Chemical distributors must ship containers using GHS-compliant labels.

- June 1, 2016 – Employers must update labeling and HazCom programs as needed.

IMPORTANT: If you are shipping overseas, you must comply with these regulations now due to the British Maritime Standard BS 5609 saltwater immersion standards.

What are the British Maritime Standard BS 5609 standards?

The BS 5609 standards are internationally recognized rules for labeling dangerous containers that will be shipped via water (maritime). In fact, these are the most stringent standards out there today due to their requirement that self-adhesive drum labels must be durable enough to withstand a three-month submersion in the saltwater of the English Channel.

Label manufacturers test their products to ensure compliance with the highly regarded BS 5609 specifications. Therefore,

any label with a BS 5609 certification guarantees the highest level of durability and full compliance with merchant shipping regulations, International Maritime Dangerous Goods (IMDG), and GHS mandates.

For questions about GHS, HCS, or BS 5609 regulations, visit

www.osha.gov. To learn more about compliant labels and printers,

contact System ID.